China High-Quality Amorphous Sio2 Manufacturers Suppliers - High Tear Resistance Fumed Silicone Rubber HTV Silicon Rubber Raw Material – Fushite

China High-Quality Amorphous Sio2 Manufacturers Suppliers - High Tear Resistance Fumed Silicone Rubber HTV Silicon Rubber Raw Material – Fushite Detail:

Product Advantages

1.High Temperature: Silicone rubber applicable temperature from -50°C to 250°C, it can be used in microwave and oven.

2.Easy to Clean: Silicone rubber finished products just need water to do cleaning.

3.Long Life: Silicone rubber stable in chemical properties.

4.Soft and Comfortable: Benefit from silicone rubber softness, molding products comfortable touch, extremely flexible and not deformed.

5.Environmentally Friendly: Silicone rubber does not produce and toxic or hazardous substances from raw materials to finished products.

6.Electrical Insulation Performance: Silicone rubber have high resistivity.

7.Low Temperature Resistance: Silicone rubber in – 60°C to – 70°C still have good elasticity.

8.Conductivity: Silicone rubber have good conductivity when add conductive material (such as fumed silica).

9.Weather Fastness: Silicone rubber is not effected by ozone, long time in Ultraviolet light and other climatic conditions, its physical properties are only slight changed.

10.Thermal Conductivity: Silicone rubber have good thermal conductivity when add some raw materials.

11.Radiation Resistance: Radiation resistance of phenyl-containing silicone rubber is greatly improved.

Application

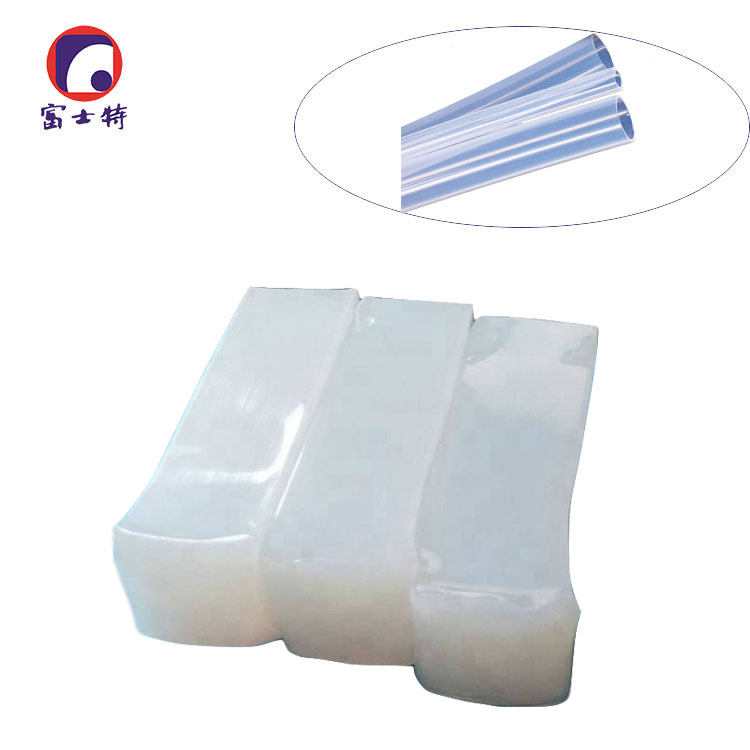

They are applicable to molding, and can be used in food contact grade and

medical grade with special requirement for high transparency. After curing the

product can be used at -50℃~250℃.

Vulcanization method

It can be cured by peroxide or platinum.

The material combining the advantages of general purpose silicone rubber with those of addition-curing liquid silicone rubber, namely outstanding mechanical properties with high throughput.

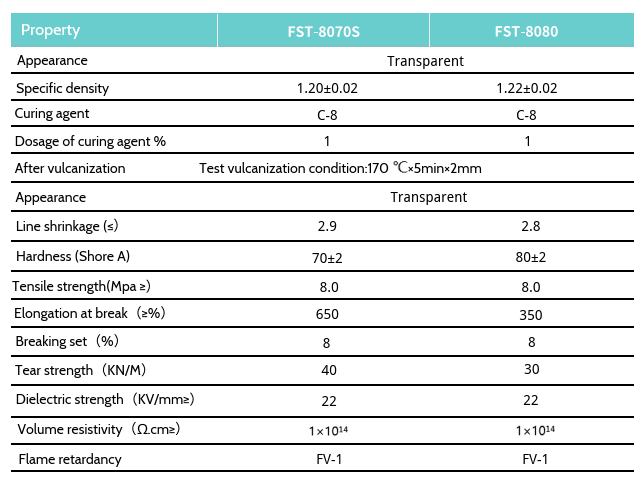

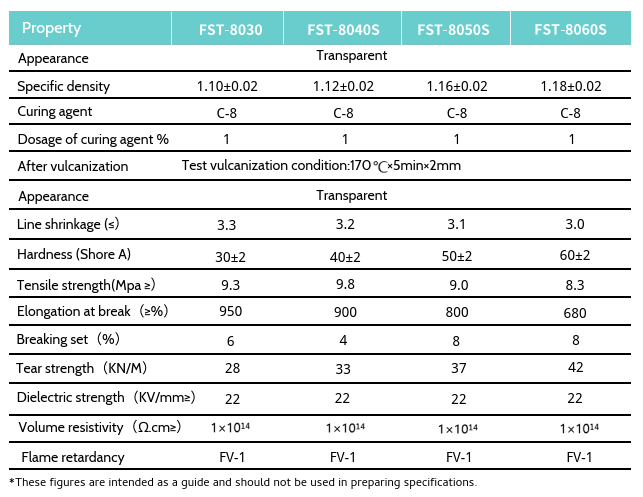

Product parameters

Fushite offers two types of solid silicone rubber: FST-80 series and FST-70 series. They are all fumed grade silicone rubber. They can be processed by conventional methods, such as extrusions, compression and transfer molding, or injection molding. They cure in heat and are ideal for manufacturing a variety of silicone rubber products.

The products in the FST-70 series have the higher transparency and namely outstanding mechanical properties combined with high productivity.

FST-70 series for Molding

The above data are based on the following measurements

Addition of curing agent: 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane

Test piece vulcanization condition: 175℃×5min, post-curing condition: 200℃×4h.

The following related materials are available, please feel free to contact us.

● Material Safety Data Sheet (MSDS)for Fumed Silicone Rubber

● FDA Test for Silicone Rubber

● RoHS and Other Restricted Substances Test for Silicone Rubber

● Substances of Very High Concern Test(SVHC)for Silicone Rubber

● High-performance Fumed Rubber(TDS)

Packing & Delivery

1. 20KG/Carton

2. 1000KG/Pallet

3. 18tons for FCL 20’GP

Pictures for your reference

|

|

FAQ

Q1.How can I get the price?

We usually quote within 24 hours after we get your inquiry.

If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q2. Can I buy samples placing orders?

Yes. And we’d like to offer 1-2kgs free samples for you.

Q3.What is your lead time?

It depends on the order quantity and the season you place the order.

Usually we can ship within 7-15 days, and about 30 days for large quantity.

Q4.What is your payment term?

This could be negotiable.

Q5.What is the shipping method?

It could be shipped by sea, by air or by express (EMS, UPS, DHL, TNT, FEDEX and ect).

Please confirm with us before placing orders.

Q6.How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for China High-Quality Amorphous Sio2 Manufacturers Suppliers - High Tear Resistance Fumed Silicone Rubber HTV Silicon Rubber Raw Material – Fushite , The product will supply to all over the world, such as: moldova, Honduras, Johor, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.